Unveiling the Wonders of Flexographic Printing Machines in Today's Market

Jan 24,2026

Image Source: unsplash

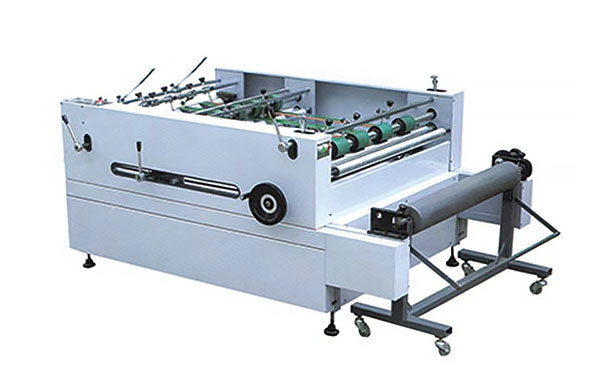

Introduction to Flexographic Printing Machines

Have you ever wondered how those vibrant labels and packaging materials come to life? Well, my friend, it's all thanks to the Flexographic Printing Machine, a fascinating piece of technology that has revolutionized the printing industry. In this article, we'll dive into the intricacies of flexo printing, its applications, and why it's become a go-to choice for many businesses today.

What is Flexo Printing?

Flexo printing, short for flexographic printing, utilizes flexible relief plates to transfer ink onto various substrates. It's like a modern-day magic trick, where the right combination of inks and plates results in stunning finishes. This method is not only efficient but also incredibly versatile, making it suitable for everything from newspaper printing to packaging materials.

How Does a Flexographic Printing Machine Work?

The Flexographic Printing Machine operates on a simple yet effective principle. First, the plates are created using various materials, and these plates are then mounted on rotating cylinders. As the cylinders turn, they pick up ink from an anilox roller and transfer it onto the substrate. It's a seamless process that ensures high-quality prints with minimal waste.

Advantages of Flexo Printing

- Speed and Efficiency: One of the standout features of flexo printing is its speed. The quick drying of inks allows for faster production times, which is ideal for businesses looking to meet tight deadlines.

- Cost-Effectiveness: When printing in large quantities, flexo printing can be more economical compared to other methods, especially for packaging.

- Eco-Friendly Options: Many modern flexo inks are water-based, making them less harmful to the environment.

Applications of Flexographic Printing Machines

From labels to flexible packaging, the applications of a Flexographic Printing Machine are vast. Here are a few key areas where flexo printing shines:

- Packaging: Whether it's food packaging or retail boxes, flexo printing ensures that products look appealing and professional.

- Labels: Custom labels for products are often printed using this method, allowing brands to stand out on the shelves.

- Newspapers and Magazines: High-speed newspaper printing is made possible with flexo technology, ensuring timely delivery.

The Future of Flexo Printing

As technology continues to evolve, so does the Flexographic Printing Machine. Innovations such as digital integration and advanced inks are paving the way for even greater efficiency and quality. Manufacturers are constantly adapting to market needs, ensuring that flexo printing remains relevant in an ever-changing landscape.

Conclusion

In a nutshell, the flexo printing machine is a cornerstone of modern printing. Its ability to produce high-quality prints quickly and efficiently makes it an invaluable asset across various industries. So, the next time you pick up a product with a vibrant label, remember the magic behind it—flexo printing at work!

PREVIOUS:

Related Posts

Contact Us

E-mail:

alice@zhenhua-packing.com

Phone/WhatsApp:

+86-15132759995

Address:

No. 70, Bajie Village, Lianzhen Town, Dongguang County, Cangzhou City, Hebei Province