The difference between different die cutter machines

Sep 11,2023

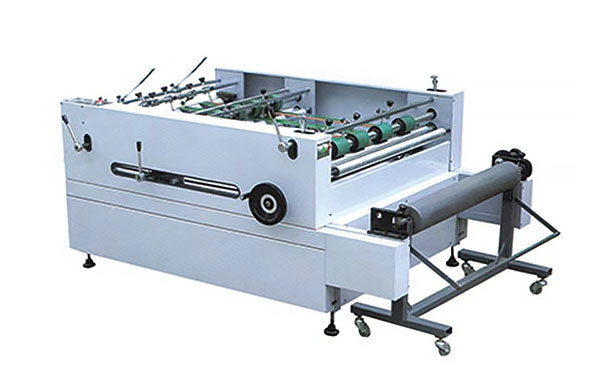

Die cutter machine classification

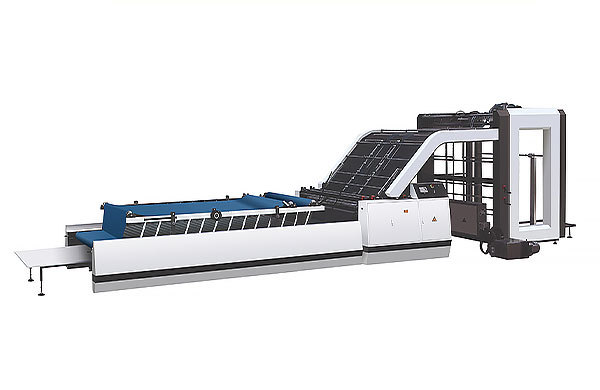

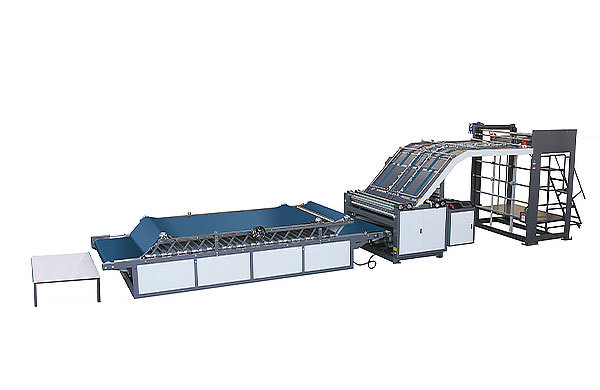

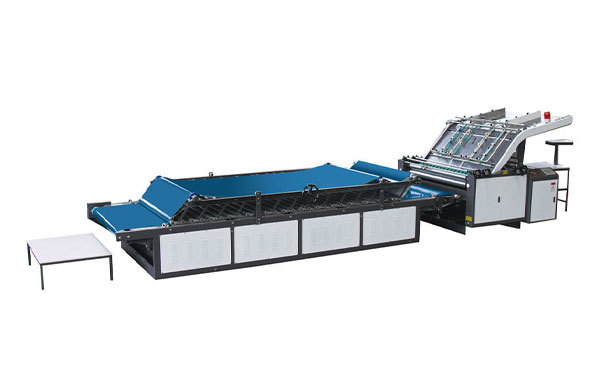

★ According to the different embossing forms, the die cutter machine is mainly divided into three types: rotary die cutting, rotary flat die cutting and Flatbed die cutting.

★ According to the form of die cutting plate placement, it can be divided into vertical type and horizontal type.

★ According to the degree of automation, it can be divided into manual (semi-automatic) and automatic.

★ In terms of function, in addition to die-cutting, there is also a stamping function, which is called a hot stamping die cutter machine, and some have an automatic waste removal function, called a waste-removal die cutter machine.

The rotary die cutter machine is characterized by linear contact, low die-cutting pressure, and high production efficiency. It can be connected with offset printing machines, flexo printing machines, gravure printing machines and other printing equipment for in-line die-cutting, so it has a wide range of applications. One cylinder is equivalent to the impression cylinder, which applies pressure during die cutting; the other is the roller die.

There are two types of roller dies: wood and metal. The former mainly die-cuts very thick corrugated cardboard, while the latter has metal roller dies processed by chemical corrosion or electronic engraving, which are mainly used for die-cutting self-adhesive labels and trademarks. , There is also a metal roller die mainly used for medium and high-end long-term products, which adopts the form of pressure cutting or shearing.

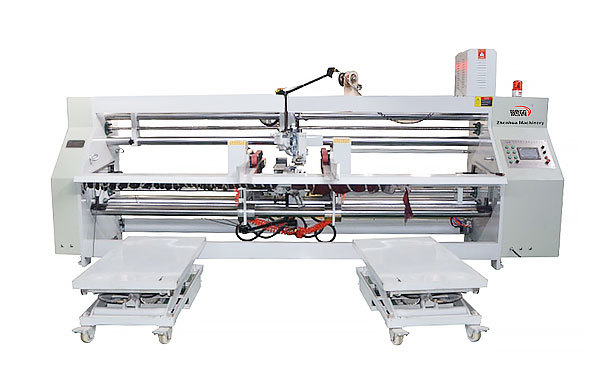

The vertical flat die cutting machine is mainly divided into two parts: the fuselage and the press frame. The die-cut plate is mounted on the fuselage. According to its action mode, there are two types: single pendulum and double pendulum. The single pendulum type means that when die-cutting, the press frame swings, the body does not move (that is, the plate table does not move), the plate table and the lower part of the press frame contact first, and then the upper part contacts. In this way, the stress time is different, and the stress is uneven, so it is used less and less, and it is gradually eliminated.

The double pendulum type means that during die-cutting, both the fuselage and the press frame move. Before the contact, the press frame lithography plate and the plate table are parallel, and the contact form between them is parallel movement, so the pressure is large and uniform. Most of the vertical flat die-cutting machines currently produced belong to this type. Vertical flat die cutting machine can be divided into semi-automatic and fully automatic according to the degree of automation.

Related Posts

Contact Us

E-mail:

alice@zhenhua-packing.com

Phone/WhatsApp:

+86-15132759995

Address:

No. 70, Bajie Village, Lianzhen Town, Dongguang County, Cangzhou City, Hebei Province