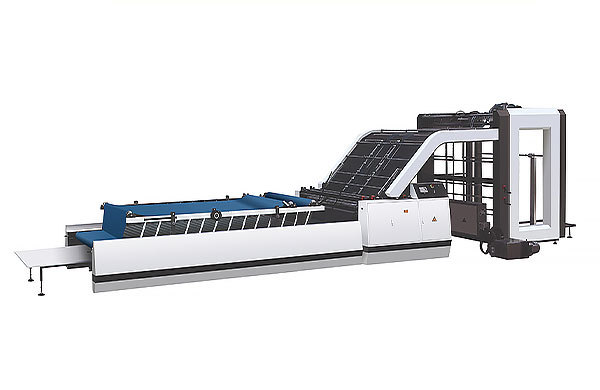

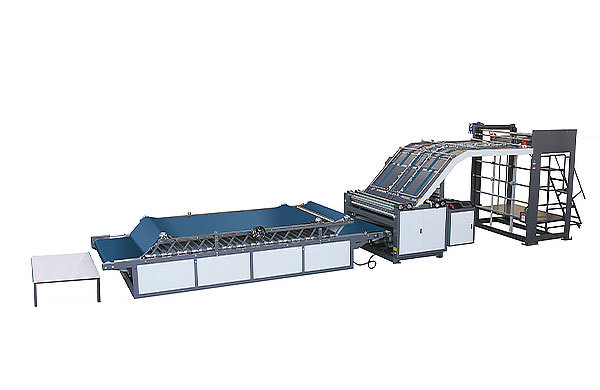

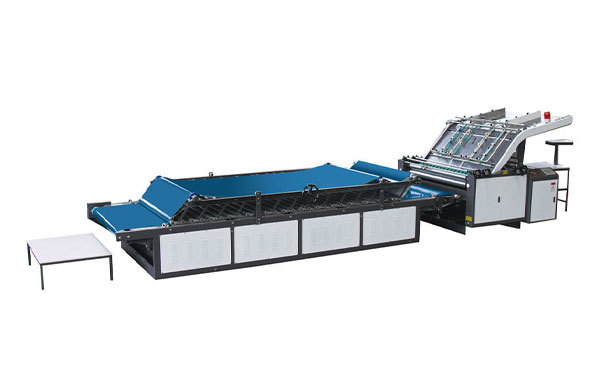

How to correctly debug the corrugated box stitching machine?

Sep 11,2023

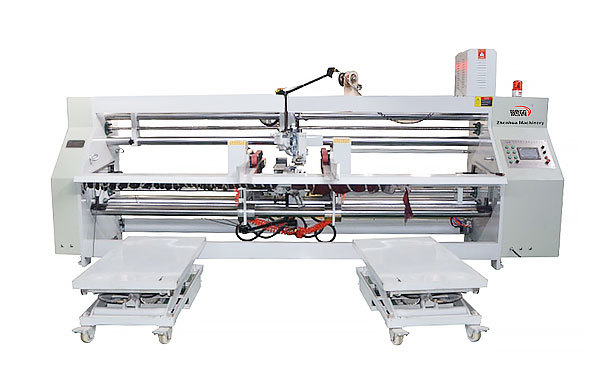

The carton equipment adjustment should avoid blindness. Adjust the positions of the main baffle, left and right baffles, and the positions of the upper and lower nail heads according to the flap of the carton. Pay attention to the left and right baffles not to be clamped too tightly, and ensure that the cardboard can be inserted and pulled out smoothly.

After the mechanical adjustment is completed, set the touch screen computer: such as the height of the carton = the height of the original carton -40mm, the number of nails in the carton, the nail distance of the carton, the setting of whether to strengthen nails, etc., the selection of single and double sheets, etc. After all the above tasks are set up, trial production can be carried out.

If the thickness of the cardboard is too thick, personnel should be arranged to properly thin the binding part so that the tissue paper will not be crushed during binding. The nailing should be carried out in accordance with the requirements of the production notice, and the box nails should be nailed along the center line of the overlapping part, and the deviation should not exceed 3mm.

The nail distance should be uniform, the first and tail nails are 20mm from the upper and lower lines, the single nails are not more than 55mm, and the double nails are not more than 75mm. The two pieces of box blanks should be aligned, and there should be no overlapped nails, missing nails, warped nails, broken nails, bent nails, and no corners.

After the order is completed, the folded box of the carton should be square. The difference between the two diagonals of the top surface of the carton with a comprehensive size less than or equal to 1000mm should not be greater than 3mm. The comprehensive deviation of the inner diameter of the single corrugated box should be within ±2mm, and the double corrugated box Within ±4mm, the difference between the two diagonals of the top surface of the carton with a comprehensive size greater than 1000mm shall not be greater than 5mm, the comprehensive deviation of the inner diameter of the single-tile carton shall not be greater than 3mm, and the double-corrugated box shall not be greater than 5mm. The hole diameter of the box corner shall not be greater than 4mm2, and there shall be no obvious wrap angle, and the seam or overlap of the outer flap shall not be greater than 2mm.

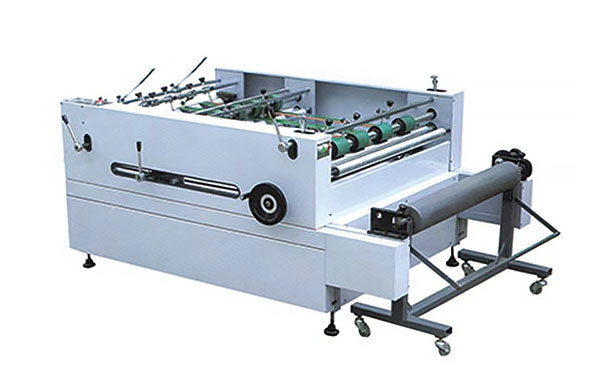

The nail box shall not have the phenomenon of inverted head nails, and the two pieces of box blanks with inconsistent yin and yang surfaces, varieties, and specifications shall not be mistakenly stapled together. The ordered cartons will go into production after being inspected and qualified. When the nail box starts, the cardboard is fed by the servo motor, and the nail car motor drives the nail head to complete the nail box. The drive shaft driven by the nail head motor and equipped with a clutch and brake drives the crank mechanism to realize the nail box action under the action of the clutch. When the first nail action is completed, the cardboard backplane picks up the cardboard, and the crank mechanism moves in a stepping manner. Drive the paper feed roller to rotate, stop after reaching the predetermined nail pitch, and immediately perform the second nailing action.

The key to the nail box machine is the quality of the nail car and the nail head, and product quality failures often occur here.

Related Posts

Contact Us

E-mail:

alice@zhenhua-packing.com

Phone/WhatsApp:

+86-15132759995

Address:

No. 70, Bajie Village, Lianzhen Town, Dongguang County, Cangzhou City, Hebei Province