Share to

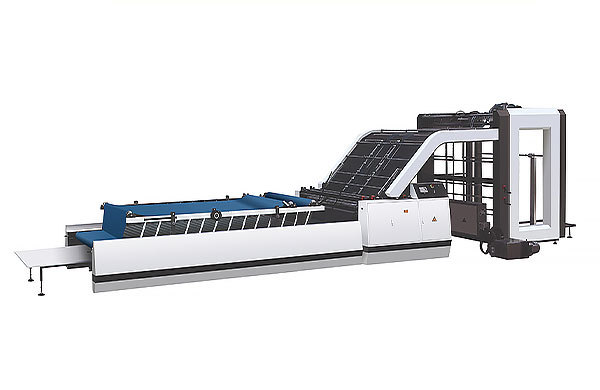

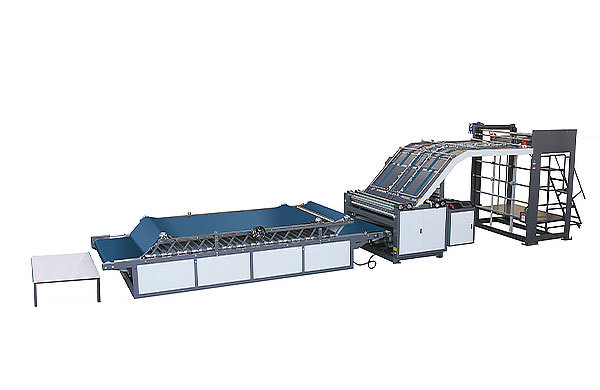

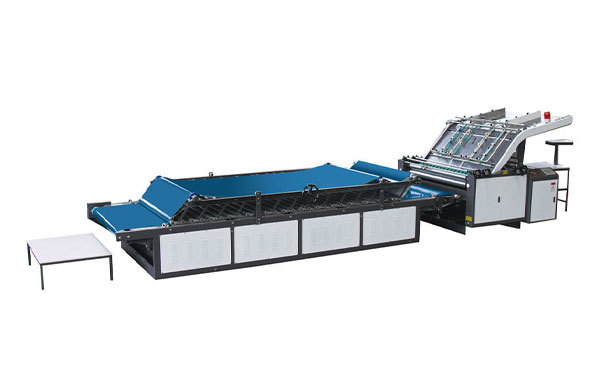

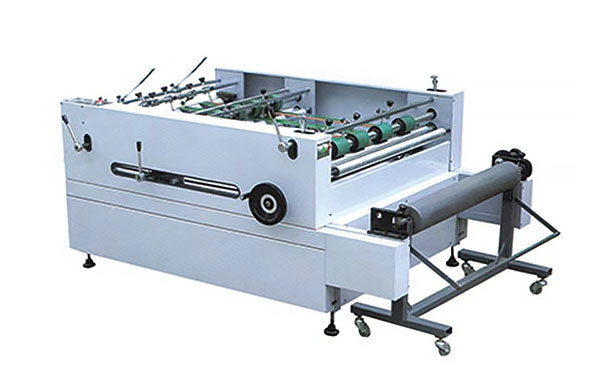

GQXF High-Definition Vacuum Transfer Automatic Printing Glazing Drying Die-Cutting Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Details

- Machine Unit

-

Machine Features

★ High Precision: +0.3mm accuracy is derived from servo drive, No pressure feeding system and vacuum absorption transmission.

★ High definiton: 130Lpi Printing Line, Originated from Closed doctor blade with Ceramic anilox Roller and Precision Pressure Regulating System.

★ High efficiency: Paper feeding, dust removal, printing, infrared drying, polishing,infrared(ultraviolet)drying, die cutting and stacking. complete the production process at one time. The production speed is between 100 and 150 pcs per minute.

★ High Quality: CNC Intelligent Control System is used to cooperate with Germany Bosch Rexroth to achieve long-distance maintenance through network and ensure long-term stable operation of equipment.

★ The whole machine is adopted international famous brand appliances and computer software, the quality is stable and reliable. Man-machine interface, Multi-set touch screen control, computer order management, easy to operate. Replace the order faster (can be stored 999 orders in advance).

★ Whole wallboard and important components are adopted aging treatment, eliminate the metal internal stress; Adopt high precision machining centers, CNC grinding machine for grinding processing.

★ The machine shaft, roller are adopted high quality steel, grinding processing, high precision computer dynamic balancing correction and surface hard chromium plating.

★ The engine drive gear is adopted 20CrMnTi alloy steel, carburizing, quenching treatment, hardness HRC58-62 and gear grinding processing precision level 6, and ensured the long-term use of tinted with high precision.

★ Machine transmission parts (shaft, gear joint) are adopted free key connection (LOCK-ALX), the connection eliminate clearance. It is suitable for long-term high speed with high torque.

★ The engine lubrication system is adopted automatic spray type lubrication, Equipped with automatic balancing device, keep the oil in every units at the same level.

★ The machine is adopted adjustment preset functions, feeding, printing, slotting, die- cutting, automatic zero resetting, Separate and combine memory automatic reset.

★ There is lack of ink alarm device and the real-time monitoring for the ink working condition system.

Technique Parameter

Modle 920 1226 1428 1630 Wall board thickness(mm) 60 60 60 60 Wallboard distance(mm) 2000 2600 2800 3000 Max Machine Speed(pcs/min) 350 300 200 180 Economic Working Speed(pcs/min) 100-250 100-250 100-180 80-150 Max. Feeding Size(mm) 900x1750 1200x2350 1400x2550 1600x2750 Max. Printing Size(mm) 900x1600 1200x2200 1400x2400 1600x2600 Min. Feeding Size(mm) 260x500 290x500 380x600 450x700 Skip-feeding Size(mm) 1100x1750 1500x2350 1700x2550 1800x2750 Standard Plate Thickness(mm) 7.2 7.2 7.2 7.2 Min. slotter distance positive 145x145x145x145 150x150x150x150 150x150x150x150 160x160x160x160 Min. slotter distance negative 215x60x215x60 255x60x255x60 255x60x255x60 260x65x260x65 Max slotter depth(mm) 220 300 350 400 Suitable Cardboard Thickness(mm) 1.5-12 1.5-12 1.5-12 1.5-12 -

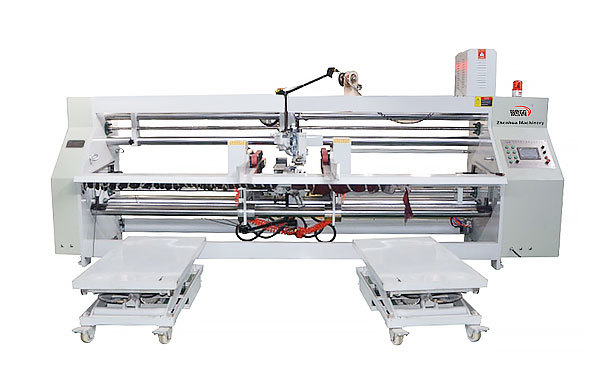

Feeding Unit

★ Servo motor independent drive, no gear clearance wear, long life, high precision.

★ Servo motor independent drive, no gear clearance wear, long life, high precision.

★ Vacuum adsorption leading edge feeding, frequency control of air volume, feeding stability, precision.

★ Extended type feeding system, according to the length of the cardboard, determine the feeding stroke size, improve the feeding accuracy.

★ Non pressure feeding system, avoid damage to the cardboard,ensure the compressive strength of the original cardboard.

★ The whole machine automatic zero system, storage common orders, quick order replacement, easy to operate.

★ Wide type dust removal device, in addition to electrostatic brush, can remove paper dust on the board surface, improve the quality of printing.

★ Left, right baffle, rear pallets are computer controlled, precision guide mechanism, smooth displacement, with side beat function.Printing Unit

★ Full vacuum adsorption, with ceramic feeding wheel transfer system.

★ Full vacuum adsorption, with ceramic feeding wheel transfer system.

★ Frequency conversion adjustment adsorption air, also according to the length of the cardboard automatically adjust the damper switch.

★ Closed doctor blade with ceramic anilox roller, high precision printing, doctor blade force uniform, simple adjustment and maintenance.

★ Pneumatic double diaphragm pump, quick cleaning function, ink supply, stable circulation, simple operation and maintenance.

★ Quick replacement of rubber roller, anilox roller device, with fast replacement of support.

★ Tilting correction roller, the tilting error of the print plate can be quickly corrected on the plate roller, hanging plate is convenient and fast.

★ Memory Location Function, automatic reset system.Varnishing Unit

★ The fixed unit of the polishing unit is widened, which helps with the drying speed of the varnish.

★ The fixed unit of the polishing unit is widened, which helps with the drying speed of the varnish.

★ During the production of the polishing unit, water-based gloss or UV gloss can be selected for polishing, and it can also be used as a printing unit.

★ Equipped with a paper jam sensor, making operation safer and more reliable.Drying Unit

★ Fan and Infrared (IR) drying system

★ Fan and Infrared (IR) drying system

★ Extended drying section to ensure complete drying of the board before die -cutting.

★ Segmented, and adjusted according to the size of the board.

★ Paper jam sensing protection device for safer operation.

★ Optional ultraviolet (UV) drying system.Die Cutting Unit

★ Independent servo drive, avoid impact of die cutting on the printing effect.

★ Independent servo drive, avoid impact of die cutting on the printing effect.

★ Equipped with imported fast changing polyurethane rubber, easy to replace, with a one-way clutch for linear speed compensation function, can ensure that the rubber wear out of the die- cut cardboard is exactly the same.

★ When working, the die cutting roller mechanical screw about automatic transverse movement (plus or minus 20mm), so that the cutting knife does not repeat, prolong the service life of felt sleeve.

★ The gap between rubber roll and die cutting roll is controlled by pneumatic control. Normally, the rubber roll drops to the working position when paper feeding, and the rubber roll automatically rises when paper feeding stops.

★ Rubber correction mechanism, increase the use number of rubber, reduce consumption.

★ The bottom of the die cutting equipped with a waste paper conveying device, the die cutting paper scraps to the outside of the equipment, convenient cleaning.

GQXF High-Definition Vacuum Transfer Automatic Printing Glazing Drying Die-Cutting Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!