Share to

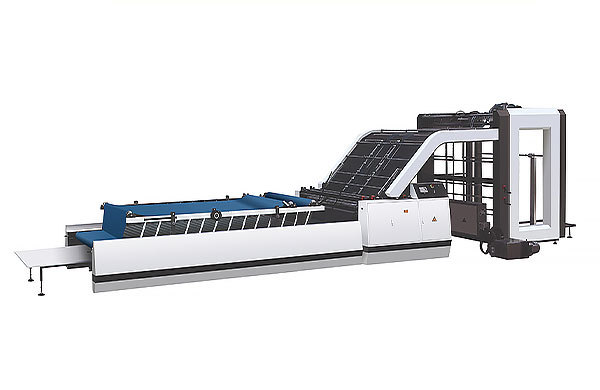

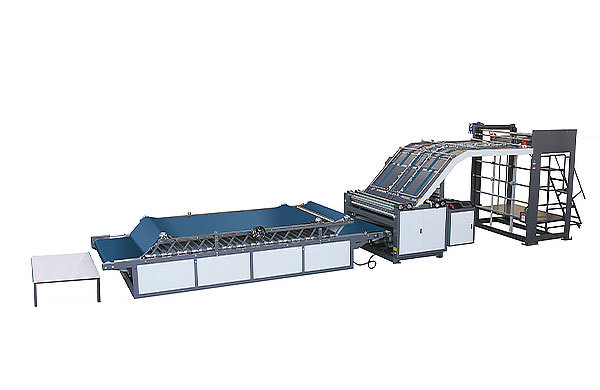

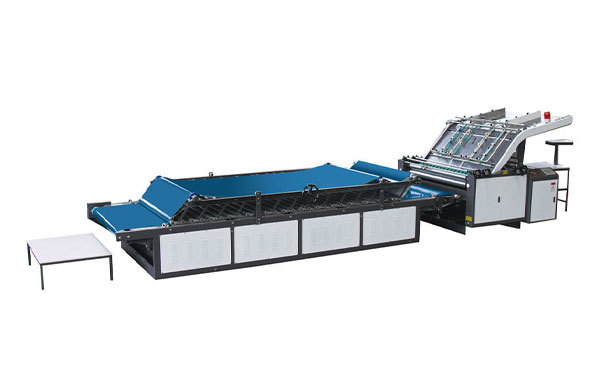

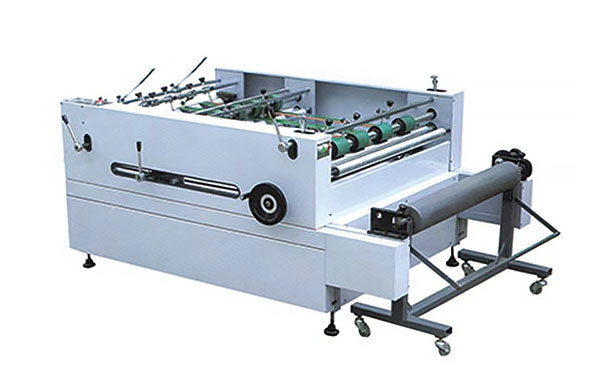

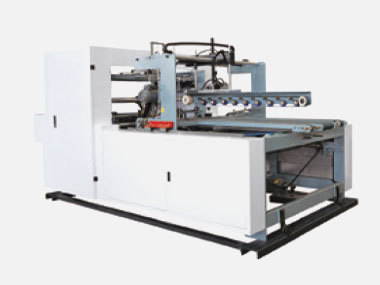

Sheet Board Pasting machine

Still deciding? Get samples first, Contact US !

View similar products

- Product Details

- Machine Unit

-

Product Introduction

The BJ series of gum mounting machine is a kind of gum mounting used to produce every kind of corrugated paperboard. This machine can mount the gum on the single and double sides of the corrugated paper with the plank paper into the corrugated paperboard. The gum mounting roller of the machine has chosen the superior quality seamless steel pipe as

its material and has the characteristics such as wear-resisting, long using life and so on.1. Adjust range of the upper glue roller distance 0-2mm.

2. Adjust range of the lower glue roller distance 0-3mm.

3. Adjust range of working roller distance 2-10mm.

4. Motor power: 1.2 kw.

Machine Can Be Customized

Model Over the paper width Over the paper thickness Working speed Shape size(mm) BJ-1600 1600mm 18mm 80m/min 2200×400×1500 BJ-1800 1800mm 18mm 80m/min 2400×400×1500 BJ-2000 2000mm 18mm 80m/min 2600×400×1500 BJ-2200 2200mm 18mm 80m/min 2800×400×1500 BJ-2500 2500mm 18mm 80m/min 3100×400×1500 -

Feeding Unit

★ Lead edge feeding paper mechanism can greatly reduce clogging phenomenon in the process of feeding cardboard paper.

★ Lead edge feeding paper mechanism can greatly reduce clogging phenomenon in the process of feeding cardboard paper.

★ Suction fan auxiliary paper feeding, to ensure bend paperboard feeding smoothly, the air volume can be adjusted for various sections according to the size of paperboard, ensure the maximize of the cardboard vacuum adsorption capacit, to make more accurate feeding paper.

★ The front baffle plate and the rear baffle adjust the gap by manual, leftright side bafle of feeding paper adjust the gap by electronic.

★ The paper feeding wheel is made of polyurethane material, high friction, long durability

★ Suitable for three, five (seven) layer corrugated board, including E type corrugated board

★ The counter of feeding paper set and display production quantity.Printing Unit

★ When the unit is separated, the pneumatic brake mechanism to limit the transmission shaft rotation, to maintain the original gear position fixed point, can achieve a smooth fit to maintain the original printing position.

★ When the unit is separated, the pneumatic brake mechanism to limit the transmission shaft rotation, to maintain the original gear position fixed point, can achieve a smooth fit to maintain the original printing position.

★ The printing roller to 360 degrees of digital phase adjustment of the computer electric motor, can be preset digital automatic adjustment (operation, stop can be adjusted).

★ Pneumatic diaphragm pump for ink stability, simple operation and maintenance; ink filter screen, filter impurities.Slotter Unit

★ With pre-creasing wheels for prevent the cardboard rupture while creasing.

★ With pre-creasing wheels for prevent the cardboard rupture while creasing.

★ Single roler with double knives sloting,the height of the carton adopt PLC and electric input data adjustment.(PLC with touch screen adjustment as an option)

★ The phase of the sloting unit adopt PLC and electric 360"adjust, accord the eror to input the adjust data,can be adjusted while the machine running or stop.(PLC with touch screen adjustment as an option)

★ The sloting knives and the creasing wheels horizontal moving adopt electric synchronous adjustment.(PLC with touch screen adjustment as an option,input the size of the carton into the touch screen,will automatic adjusting).

★ Creasing space and knife roller space adjustment adopt self -locking structure.

★ The carton height adiustment have a anticollision device for the slotting knives,will not destroy the machine.

★ The sloting knives is sawtooth,adopt aloy steel material and after heat treatment and grinded, more hardwearing and sharp-edged. Two- piece type cutting knives, sharp-edged and high precisiorn.

★ The hole and handle tool as an option.Die Cutting Unit

★ Using the precision speed control combined with the harmonic gear drive structure, thin after in plastic anvil, and working operation, still can make the rubber gasket roller linear velocity and die cutter roller, to ensure the cardboard die-cutting size accurate.

★ Using the precision speed control combined with the harmonic gear drive structure, thin after in plastic anvil, and working operation, still can make the rubber gasket roller linear velocity and die cutter roller, to ensure the cardboard die-cutting size accurate.

★ Improve the quality of the die -cutting paper products and greatly prolong the service life of the rubber gasket.Transfer Unit

★ Glue system with constant temperature.

★ Glue system with constant temperature.

★ CNC linkage control, Multiple Paper Waste Stripping System.Folding Unit

★ The folding belt is individually adjusted and controlled, and the size of the scissor opening is controlled as a standard.

★ The folding belt is individually adjusted and controlled, and the size of the scissor opening is controlled as a standard.

★ The link printing department can track the automatic acceleration or deceleration of the ink printing machine, and the adjustment is convenient and practical.

★ The folding cardboard is adjusted by belts and nylon wheels, which is convenient to adjust the angle of the folding cardboard.Tidying Unit

★ The fan drying function speeds up the carton gluing speed and can effectively reduce the production of defective products.

★ The fan drying function speeds up the carton gluing speed and can effectively reduce the production of defective products.

★ Tapping function, effectively avoiding scissors.Stacking And Counting

★ Stacking cardboard adopts mechanical insertion method to stack the height of cardboard.

★ Stacking cardboard adopts mechanical insertion method to stack the height of cardboard.

★ Special color recognition sensors control counting, allowing each package to be counted accurately.

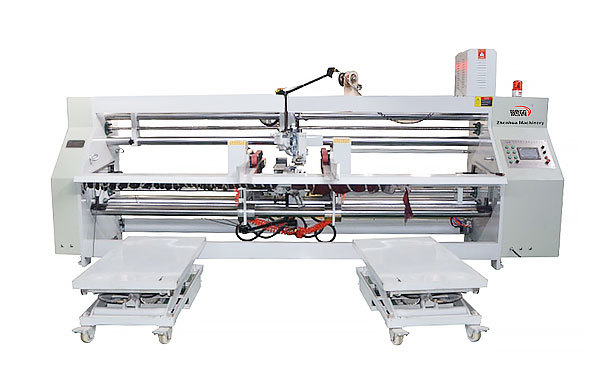

★ The counter (sensor) counting the number of cartons can be set arbitrarily on the touch screen.Packaging Unit

★ Suitable uses: carton, corrugated paper, cardboard large objects, the newspape, books, periodicals printing and the clothing packing, this machine can used for many different part.The machine control adopt mechanical (or electronic), work performance stabilization, electric power small, it only need 3 degree per day. Our machine strong and durable, easiler maintenance.

★ Suitable uses: carton, corrugated paper, cardboard large objects, the newspape, books, periodicals printing and the clothing packing, this machine can used for many different part.The machine control adopt mechanical (or electronic), work performance stabilization, electric power small, it only need 3 degree per day. Our machine strong and durable, easiler maintenance.

Sheet Board Pasting machine

Still deciding? Get samples first, Contact US !

View similar products

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!